Based on the release of the "Twelfth Five-Year Plan" for the plastics processing industry, the China Plastics Association put forward guidance for the future technological progress of the plastics processing industry. The overall requirement of the guidance is to thoroughly implement the spirit of the National Science and Technology Innovation Conference, adhere to the policy of "independent innovation, focus on cross-domains, support development, and lead the future"; accelerate the promotion and improvement of the plastics processing industry innovation system with enterprises as the main body and independent innovation as the main line Construction; promote the transformation of the development mode of the plastics processing industry, optimize structural adjustment, comprehensively improve the quality of the industry, achieve the strategic goal of developing high-end industrial chains and products, and promote the strategic shift of the plastics processing industry from large to strong.

Specific to the BOPP industry, the most important thing in terms of technology research and development is to increase the research and development of functional films, and attach great importance to and vigorously carry out "functional" technology research and nanomaterial technology research. Functional membranes are an important part of new materials in the 21st century. Various filter membranes, ultrafiltration membranes, seawater desalination, caustic soda, sewage treatment and food and pharmaceutical industries are widely used. Backsheet films and EVA rubber molds in solar photovoltaic power generation, lithium-ion and nickel-hydrogen battery separators in new energy batteries, diffusion films, prism films, composite films, optical films, etc. in flat-panel displays, as well as electrical insulation, Films for semiconductors and microelectronics, etc., are all new materials that are urgently needed and widely used in our country. These functional films still need to be imported in large quantities. An important feature of functional membranes is that the downstream market segments are particularly targeted and technically difficult. Currently, it is necessary to tackle key issues in raw material processing, impurity removal, ultra-thinning and compounding of membrane materials, and it is necessary to accelerate innovation in technology, talent, capital, etc. Gather the elements, choose the direction and focus, do your best according to your ability, and achieve new results in the development of functional membranes. At the same time, it is necessary to implement a differentiation strategy, strengthen the in-depth development of ordinary printing films, adhesive tape films, smoke films, heat sealing films, matt films, pearlescent films and other products, and improve product quality. At present, the more common BOP functional films in China include the following:

BOPP antibacterial film

Antibacterial BOPP film uses molecular assembly technology to assemble optimized antibacterial functional groups on the basic resin polypropylene molecules of the BOPP film to make polypropylene antibacterial masterbatch; when manufacturing BOPP film, one side of the film is placed on the surface or in contact with food, The surface layer of medicines and beverages is made by adding the above masterbatch with auxiliary materials in a certain proportion and bidirectionally stretching it through an extruder, so that the surface layer of the BOPP film in contact with food, beverages and medicines has an antibacterial and sterilizing effect. Antibacterial BOPP film also has the remarkable feature of high-efficiency and broad-spectrum antibacterial properties. Since the antibacterial masterbatch has good compatibility with polypropylene resin, and the assembly rate of the antibacterial functional groups is controlled through process adjustment, the antibacterial functional groups can be distributed in nanometer sizes in the antibacterial film layer, making it highly effective in antibacterial properties. It has extremely excellent inhibitory effect on a variety of harmful bacteria and molds.

BOPP capacitor film

polypropylene film is the most important raw material for film capacitors, accounting for about 70% of the cost of film capacitors. Capacitors are a basic electronic component and are widely used in various fields of the national economy, including household appliances, energy-saving lamps, hybrid Power vehicles, wind power generation, solar power generation, railway electrification, railway locomotives and energy-saving lamps and many other industries.

BOPP synthetic paper

BOPP synthetic paper is made of polypropylene and other resins and inorganic fillers as the main raw materials, and is processed through multi-layer co-extrusion and biaxial stretching. It is a multi-functional material that has the characteristics of both plastic and paper. It is a new plastic material product and an environmentally friendly product. It has the characteristics of light specific gravity, high strength, tear resistance, good printability, light shielding, UV resistance, durability, economy and environmental protection. Since the production process of synthetic paper is pollution-free and can be 100% recycled and recycled, it is a major reform in modern paper production.

BOPP anti-fog film

In food preservation and fruit packaging, due to the inherent moisture and water droplets formed in the air after freezing, it is easy to form more water droplets on the packaging film, which causes "condensation". "Condensation" creates favorable conditions for the rapid reproduction and growth of microorganisms, especially fruits and vegetables that have been mechanically damaged, which are more likely to cause rot. BOPP anti-fog film will not form water mist due to evaporation of water on the film surface under high and low temperature changes, and has a certain antibacterial and antibacterial effect. It is a new material that is rapidly developing internationally and is mainly used for fresh fruits, vegetables, salads, Edible fungi and other packaging.

BOPP laser holographic base film

BOPP laser holographic film, also called laser film, is made by molding a laser holographic image onto a BOPP film. Laser holographic film not only has a strong surface decoration effect, but also plays an increasing role in anti-counterfeiting packaging due to its good anti-counterfeiting properties and high technological content. It is widely used in light industry, medicine, food, tobacco, cosmetics, and electronics industries. Anti-counterfeiting of trademarks, securities, confidential cards and luxury handicrafts, as well as decoration and other fields. BOPP laser holographic film is divided into electrochemical aluminum foil stamping transfer type and non-transfer type. The electrochemical aluminum foil stamping transfer type is made by molding aluminum plating and gluing, then compounding with cardboard, peeling and transferring, and then surface printing processing, or compounding with heat sealing film and then peeling and transferring. Non-transferable laser holographic film is molded or aluminized and then laminated with paper products and films or directly used in cigarette packs, wine boxes, packaging boxes, food bags, gift bags, latte films, Christmas supplies, etc.

BOPP heat sealing film (smoke film)

Heat sealing film is one of the basic varieties of BOPP film. It is mainly used for printing, composite bag making or wrapping packaging. It can be divided into single-sided heat sealing film and double-sided heat sealing film. Single-sided heat sealing film, after printing patterns on the non-heat sealing layer, is combined with PE, BOPP and aluminum foil to make bags, which are used for packaging food, tea, beverages, etc. Double-sided heat sealing film can be directly heat-sealed to package food, textiles, audio-visual products, poker, etc.

In 2014, the global specialty film market output value reached US$23.5 billion. By the end of 2018, according to the current growth rate of 5%, the market output value will reach US$29.1 billion. There are currently many types of special films on the market, and their personalized and multifunctional features bring more added value to consumers. The functional film market has huge potential. If the film factory can overcome the difficulties in raw materials and technology to develop functional films, it will usher in huge business opportunities.

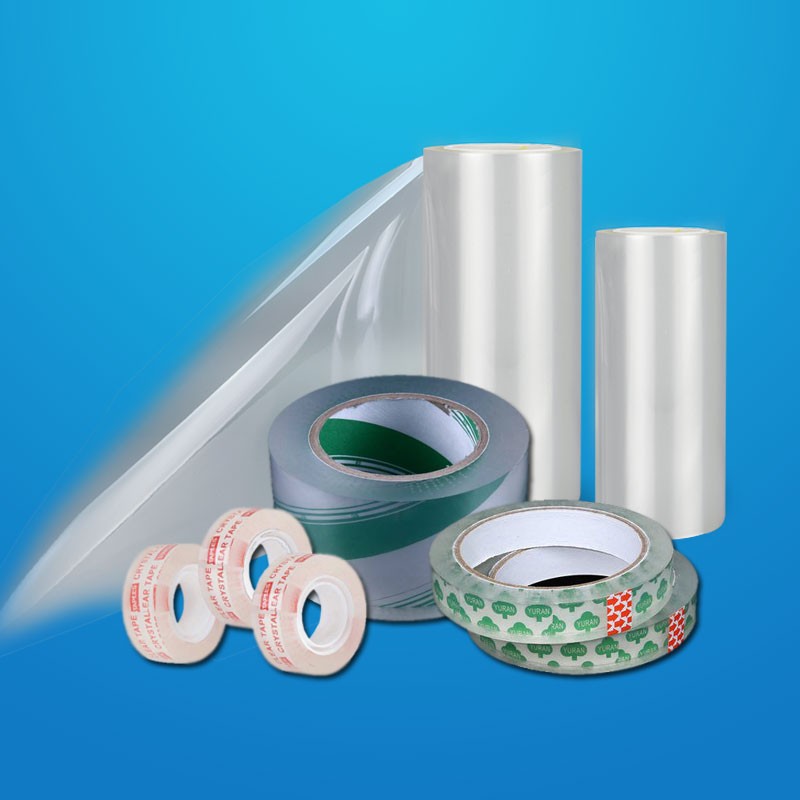

BOPP red protective film is a self-color···

BOPP protective film is a very important···

BOPP gloss film is a transparent functio···

An innovative product of functional BOPP···