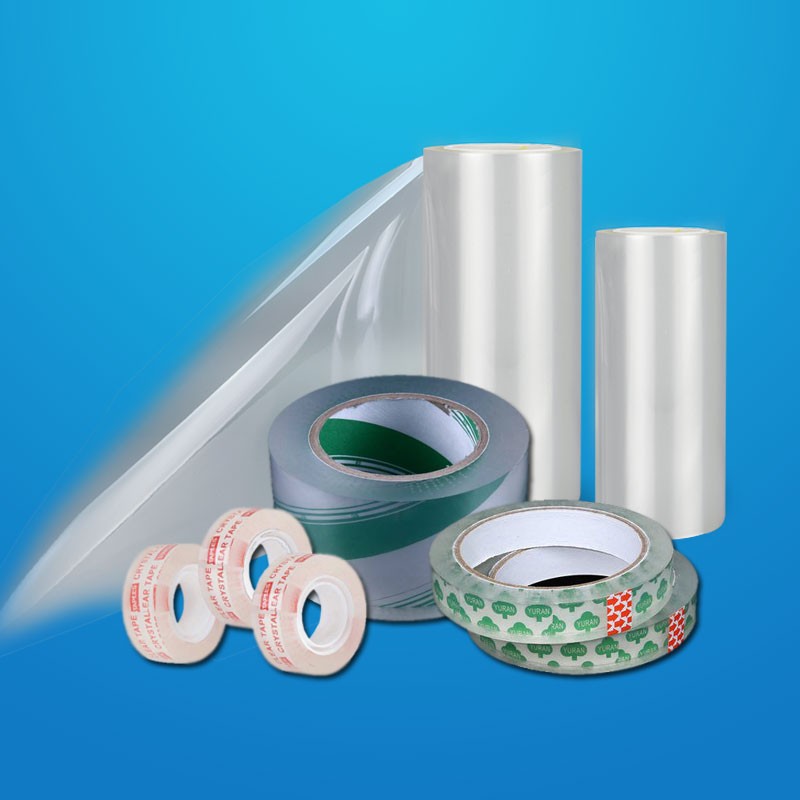

1. The full English name of OPP is Oriented Polypropylene, uniaxially stretched polypropylene film. OPP stretches the cast polypropylene film in the transverse direction and can be printed and laminated. Generally, there are two main types of product material structures: transparent and non-transparent. The transparent ones are mainly OPP/CPP, and the non-transparent ones are OPP/VMCPP. Since OPP has poor heat sealing properties, most of them are sealed by ultrasonic waves.

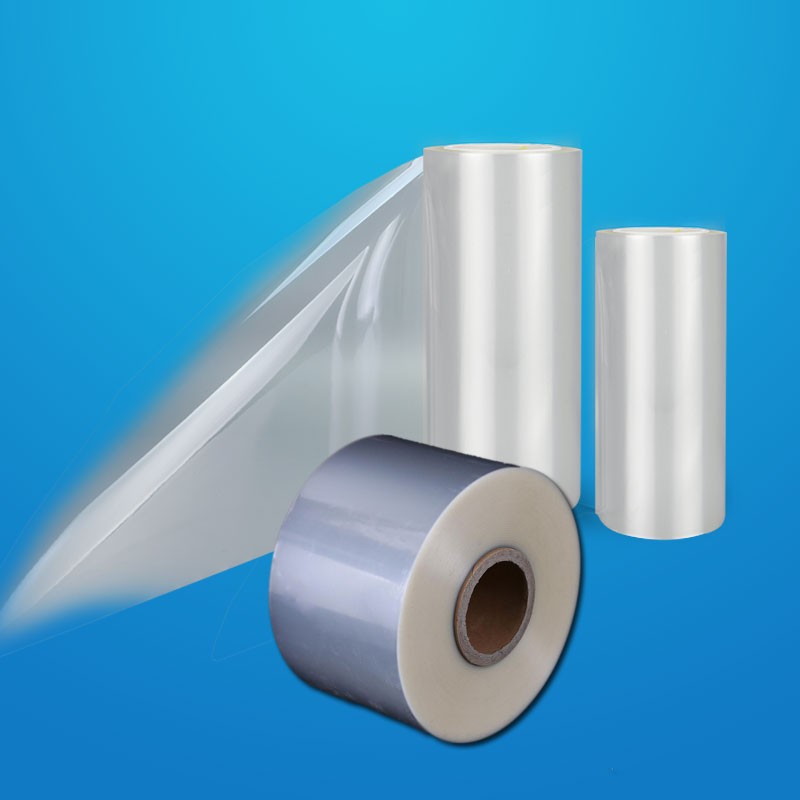

2. The full English name of BOPP is Biaxial Oriented Polypropylene, biaxially oriented polypropylene film. BOPP is a cast polypropylene film that is stretched in the transverse and longitudinal directions. It has high tensile strength, impact strength, rigidity, toughness and good transparency.

3. BOPP film is made from polypropylene particles that are co-extruded to form a sheet and then stretched in both longitudinal and transverse directions. Due to the stretch orientation, this film has good physical stability, mechanical strength, air tightness, high transparency and gloss, toughness and wear resistance. It is currently the most widely used printing film, generally with a thickness of 20 to 40 μm. The most widely used is 20 μm. BOPP is generally used as the outer film of composite films. If combined with polyethylene film, the moisture resistance, transparency, strength, stiffness and printability are ideal, and it is suitable for holding dry food. Since the surface of BOPP is non-polar, has high crystallinity and low surface free energy, its printing performance is poor and its adhesion to inks and adhesives is poor. Surface treatment is required before printing and lamination.

4. BOPP film is suitable for various packaging, printing, lamination, aluminum plating, etc., such as cigarette packaging film. It is widely used in food, medicine, daily light industry, clothing, cigarettes and other packaging material fields, and is widely used as composite film The base material is not only replacing traditional paper packaging in many occasions, but also replacing ordinary packaging films such as PE, PP, and PVC in many packaging fields.

5. OPP film is mainly used for packaging bags and forming composite materials with other materials. Single film OPP is mostly used to package lightweight products such as disposable paper cups.

BOPP red protective film is a self-color···

BOPP protective film is a very important···

BOPP gloss film is a transparent functio···

An innovative product of functional BOPP···