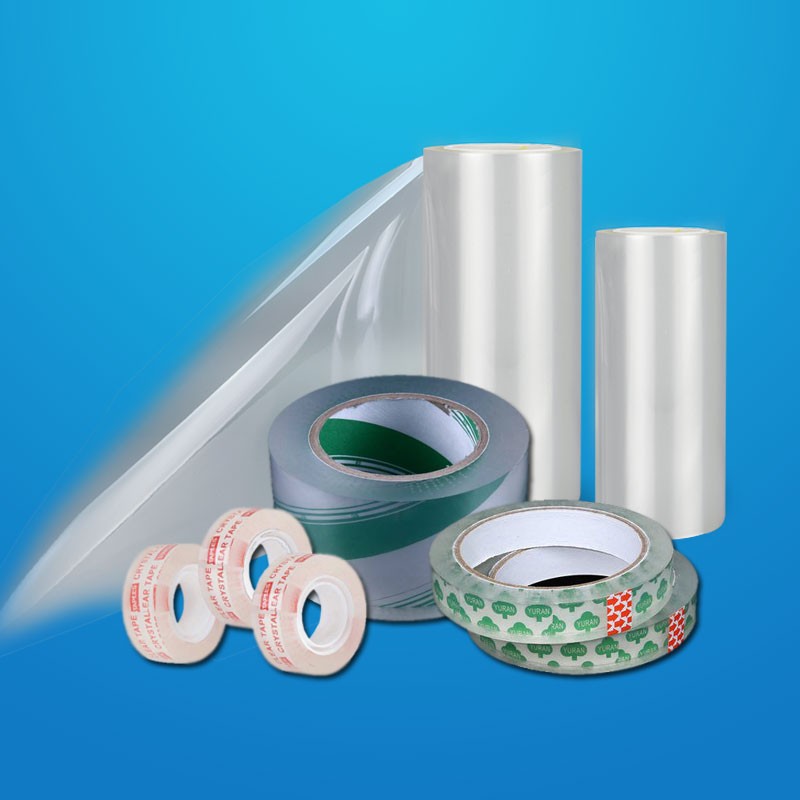

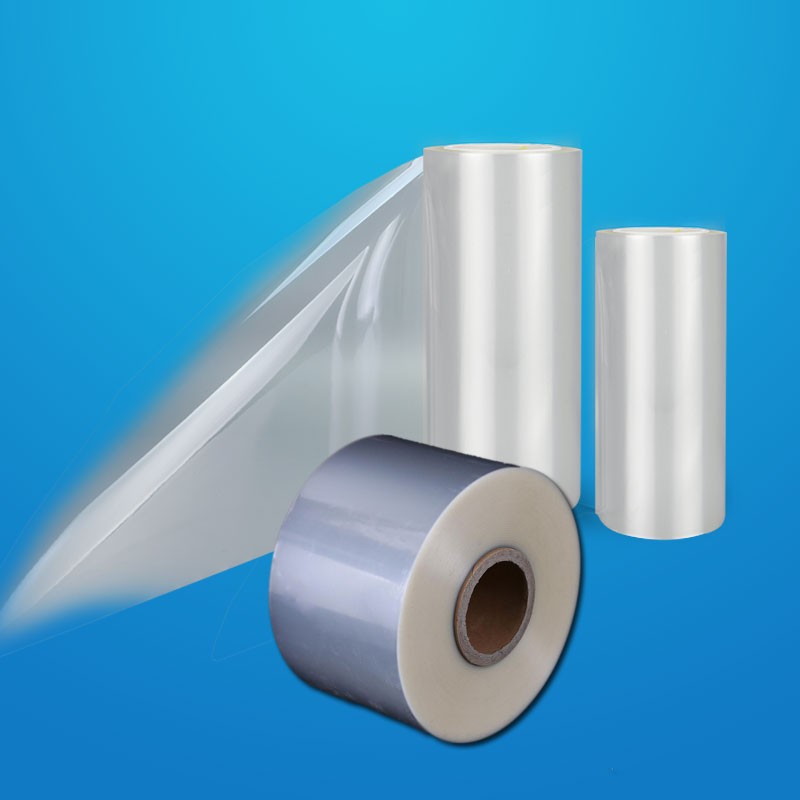

Our lives are inseparable from packaging, and the most economical and practical packaging is film product packaging. Common BOPP film products include the following varieties:

(1) BOPP light film

●Highly transparent film with low haze (≤0.3%), mainly used in high-transparent tapes, composites with paper, etc.

●Low static film, mainly used for electronic component packaging, suitable for composite slice stacking and automated packaging, etc.

●Abrasion-resistant film, mainly used for refrigeration sealing bags or knitwear packaging, etc.

●Long-lasting corona film, the product can maintain a high corona value for a long time and is used for high-speed printing, lamination, coating, etc.

●High stiffness film with good texture can reduce film thickness and cost.

(2) BOPP heat sealing film

●Ultra-low temperature heat sealing or heat sealing with wide temperature range (80-135℃), high smoothness and high corona retention value (more than 42mN/m in 6 months) heat sealing film, mainly suitable for high-speed printing composite packaging and large performance differences packaging equipment

●High heat sealing strength (5-12N/15mm) heat sealing film, replacing composite film for direct printing and bag making

●Low static heat sealing film for powder packaging

●High stiffness heat sealing film, improve packaging speed and reduce costs, reduce thickness, reduce costs

●Special packaging heat sealing film for straws, which requires appropriate transparency, gloss, friction coefficient and heat sealing strength

(3) BOPP matt film

●There are few or even no defects in appearance, suitable for lamination with dark paper products

●Can be plated with aluminum, the aluminum plating has strong adhesion, and the colored aluminum plating has a silk texture

●Good processing performance when applying UV ink or hot stamping

●High stiffness, can reduce thickness (20μm-18um-15μm), easy for composite processing

(4) BOPP smoke film

●Haze ≤ 0.8%, gloss ≥ 102%, elastic modulus ≥ 2 500MPa, the cigarettes have beautiful appearance after packaging, and the patterns are clear and bright

●The friction coefficient is less than 0.15, suitable for high-speed packaging (800 packages/min)

●High wear and scratch resistance, requiring the product to be transported to the destination without any unclear feeling due to friction.

●Positionally embossed high-security cigarette film; in order to reduce costs, it is required to reduce the thickness of the cigarette film, usually 21-23μm, now it is reduced to 16-18μm

(5) BOPP pearlescent film

●Uniform thickness, density ≤0.7g/cm;; light transmittance ≤48%, whiteness ≥88%

●Heat sealing strength ≥1.2N/15mm

●Good cold resistance

At present, the demand for environmentally friendly label films in the market is increasing, requiring high stiffness, low static electricity, high gloss, high whiteness, good pearlescent color and excellent printing composite performance.

(6) BOPP synthetic paper

●BOPP synthetic paper is currently a product that domestic BOPP manufacturers are competing to develop and has a promising market prospect. High-end products need to be produced using a 5-layer co-extrusion production line.

(7) BOPP aluminum-plated substrate film

●With the improvement of people's packaging requirements and the strengthening of quality awareness, the high water resistance of BOPP aluminized film will definitely replace BOPET aluminized film

●Requires high gloss, high rigidity, heat sealability, high barrier properties, etc.

(8) BOPP laser film (laser molded film)

●The non-transferable laser film is molded and aluminized and then compounded with paper products or films, or directly used in the packaging of cigarette boxes, medicine boxes, cosmetic boxes, food boxes or bags, etc.

●Transferable laser film, the product is molded, aluminum-coated and glued, then laminated with cardboard, peeled off and transferred and then surface printed, used as anti-counterfeiting cigarette boxes or medicine boxes, etc.; laminated with heat-sealing film, peeled off and transferred, used as anti-counterfeiting food Waiting for packaging

●The transferable laser film requires complete transfer of the aluminum-plated layer of the product, fast peeling speed, and no abnormal phenomena such as reverse sticking. The product can maintain good transfer effects for a long time.

(9) BOPP twist film

●Used for candy twist packaging. Due to environmental and health requirements, BOPP will replace PVC materials. Its price is superior to BOPS, BOPET twist film and cellophane, and it has strong competitiveness.

(10) BOPP anti-fog film

●Mainly used for packaging fresh fruits, vegetables, etc., to clearly see the contents when refrigerated, and to prevent food crystals from deteriorating and rotting.

●Good anti-fog effect (anti-fog in both hot and cold conditions), breathable, good heat sealing performance, soft

(11) BOPP stretch film

●Mainly used for the protection of fishing poles, golf clubs and other industrial products

●The product has high tensile strength, good stability and few appearance defects.

BOPP red protective film is a self-color···

BOPP protective film is a very important···

BOPP gloss film is a transparent functio···

An innovative product of functional BOPP···